Rendering is the application of a plaster coat to the walls of a building; it is a building technique used countless times.

Applying a coat of render requires the coating to be made out of a mixture of cement, sand, water and sometimes lime.

Rendering differs from plastering in that rendering involves applying a render coat of plaster to the external walls of a building while plastering involves applying the plaster coat to internal walls of a building. Another key difference is that rendering uses a more coarser type of sand compared to the more smoother sand used for plastering.

Rendering is used for a variety of reasons such as making the walls of the external building water proof and resistant to weathering and erosion, improving the value of the the property, hiding the damaged bricks of the property etc.

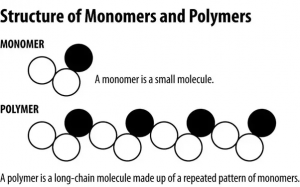

There are a variety of render coats to choose from: K Rend render has additives (polymers – self-repeating chemical compounds) added to the render mixture which makes the render coat water-resistant and strong possibly due to the polymer additive repelling the water away from the surface of the render, which prevents erosion and weathering of the brick layer) and the polymer additive may ensure the render coat sticks to the underlying brick layer strongly and prevent the render from cracking.

Pic A – a house that has been rendered in Greece; note how smooth and aesthetically pleasing the render coat has made the property appear

Pic B – diagrams to explain what a polymer is and what it is made out of; note – the plastic shopping bags you use are made from a type of polymer obtained and processed from crude oil

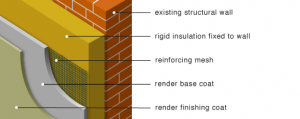

Pic C – A diagram to show how render coats are applied to a brick wall